Get Your Free Quote…!

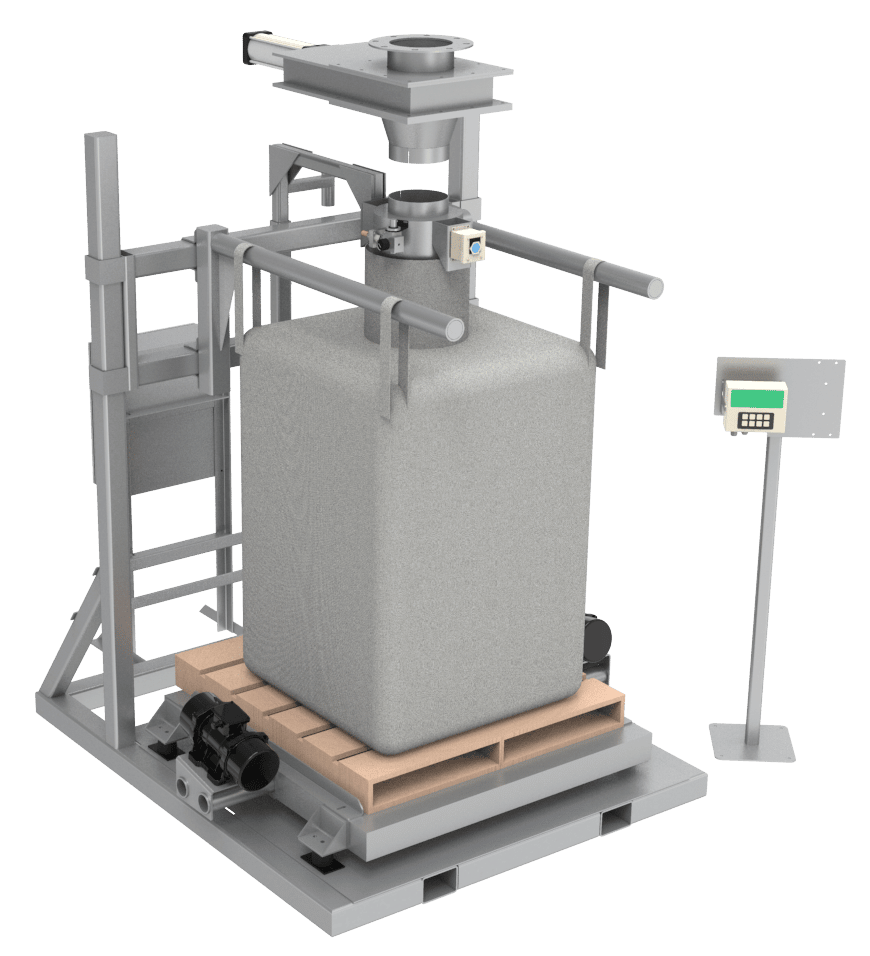

A big bag filling system is a comprehensive solution designed to facilitate the efficient filling of large flexible containers, commonly known as big bags or FIBCs (Flexible Intermediate Bulk Containers). This system offers numerous features, applications, and benefits:

*Description:*

A big bag filling system typically consists of an automated or semi-automated machine that accurately dispenses and fills bulk materials into the big bags. It often includes components such as a weighing system, conveyor belts, material dispensing mechanisms, dust containment systems, and control interfaces.

*Features:*

1. *Precision Filling:* Ensures accurate and consistent filling of big bags, minimizing wastage and product loss.

2. *Automation:* Many systems are automated, reducing the need for manual labor and increasing operational efficiency.

3. *Versatility:* Can handle a wide range of bulk materials, from powders and granules to aggregates and chemicals.

4. *Customization:* Adjustable to accommodate different bag sizes, materials, and specific production requirements.

5. *Dust Control:* Equipped with dust containment mechanisms to maintain a clean and safe working environment.

6. *Safety Measures:* Built-in safety features protect operators and prevent accidents during the filling process.

7. *Integration:* Can be integrated into existing production lines for seamless material handling.

8. *Data Tracking:* Some systems offer data collection and reporting capabilities for production monitoring and quality control.

*Applications:*

1. *Construction:* Filling bags with cement, sand, gravel, and other construction materials.

2. *Chemicals and Pharmaceuticals:* Dispensing bulk chemicals, powders, and pharmaceutical ingredients.

3. *Food and Agriculture:* Filling bags with food ingredients, agricultural products, and pet food.

4. *Mining and Minerals:* Handling minerals, ores, and other mining-related materials.

5. *Petroleum and Plastics:* Filling bags with plastic pellets, resin, and other petroleum-based products.

6. *Environmental Solutions:* Managing hazardous waste and recyclable materials during cleanup and recycling operations.

*Benefits:*

1. *Efficiency:* Increases production speed and reduces labor requirements, boosting overall efficiency.

2. *Accuracy:* Ensures precise filling to meet weight and quality specifications consistently.

3. *Cost Savings:* Minimizes material wastage and reduces the need for manual labor, leading to cost savings.

4. *Safety:* Enhances worker safety by minimizing exposure to dust and manual handling risks.

5. *Flexibility:* Can adapt to different material types and production needs, offering operational flexibility.

6. *Compliance:* Helps meet industry standards and regulations for accurate material handling.

7. *Product Quality:* Prevents contamination and maintains product integrity during the filling process.

In summary, a big bag filling system is a versatile solution that optimizes material handling processes, offering accuracy, efficiency, and safety across various industries, ultimately contributing to improved productivity and product quality.

Filter Using Product Tags