Jumbo Bag Packing Machine

Jumbo Bag Packaging Machine

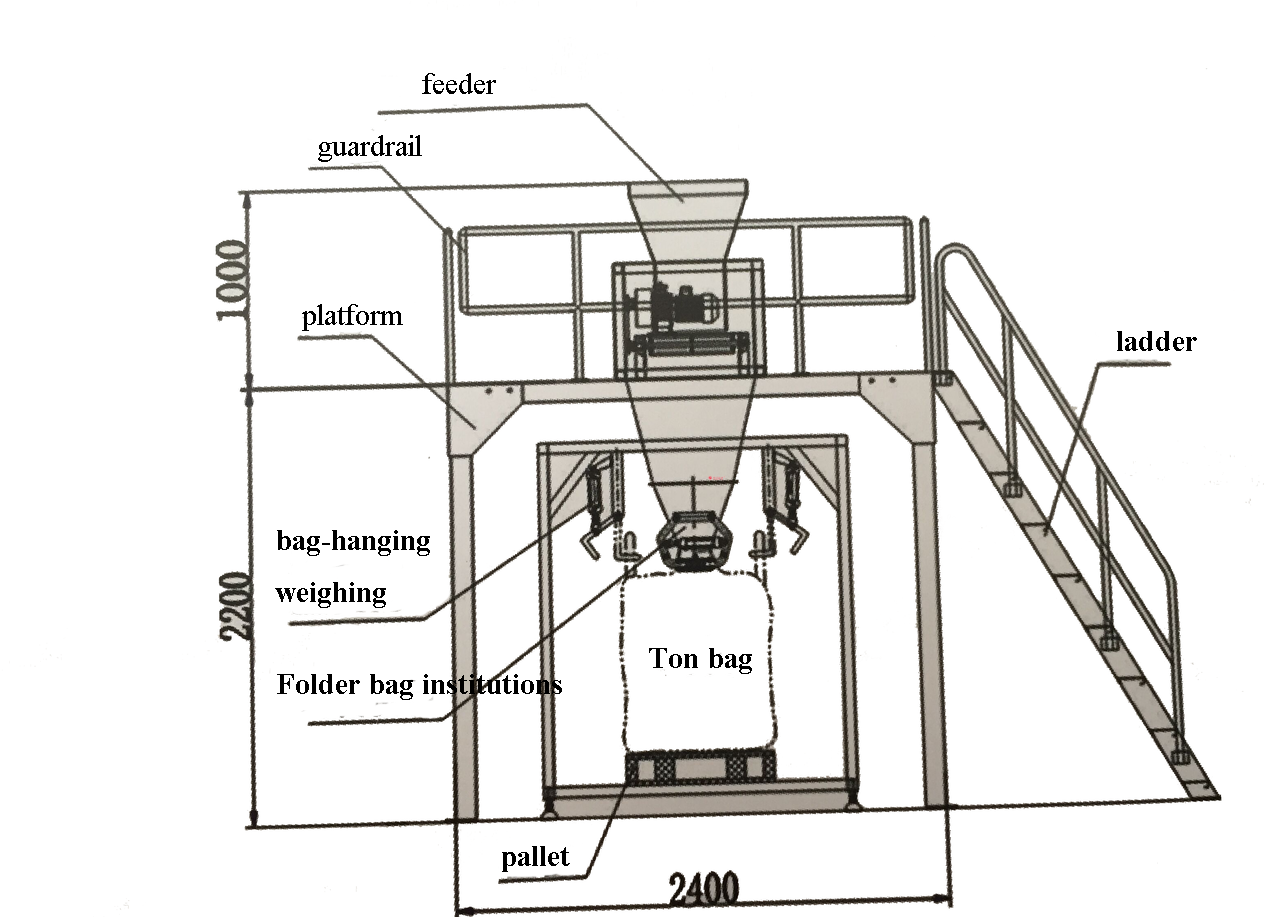

A jumbo bag packaging machine is a specialized equipment designed to automate the packaging of bulk materials into jumbo bags, also known as FIBCs (Flexible Intermediate Bulk Containers) or big bags. These machines are commonly used in industries dealing with large quantities of products such as grains, minerals, chemicals, and construction materials.

The jumbo bag packaging machine efficiently handles the entire packaging process, including filling, weighing, and sealing the jumbo bags. It ensures accurate measurement of the product and precise filling into the bags, maintaining consistency in weight and quantity. The machine is capable of handling jumbo bags of various sizes and designs, accommodating the specific requirements of different industries.

With advanced control systems and sensors, the jumbo bag packaging machine offers high-speed operations while maintaining packaging accuracy. It can be programmed to set target weights for each bag, enabling optimal filling and minimizing product waste.

These machines are designed for user convenience, featuring user-friendly interfaces that allow operators to adjust parameters, monitor the packaging process, and make necessary adjustments as needed. Some models may also include data recording capabilities, allowing for production data storage and traceability.

By automating the jumbo bag packaging process, these machines significantly improve productivity, reduce labor costs, and enhance packaging efficiency. They ensure secure packaging, convenient storage, and efficient transportation of bulk materials, meeting the demands of industries that deal with large-scale packaging requirements.

Request A Quote