Get Your Free Quote…!

A PVC 25 kg bag packaging machine is a specialized equipment designed to automate the process of packaging PVC (Polyvinyl Chloride) material into 25 kg bags. This type of machine is commonly used in industries involved in PVC production, such as construction, plumbing, electrical, and manufacturing.

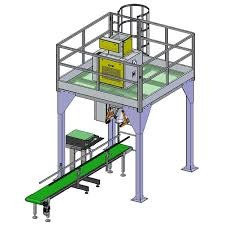

The machine typically includes features like bag feeding, material weighing, filling, and sealing. It ensures accurate and efficient packaging of PVC in predetermined quantities. The bags are often made of durable materials to withstand the weight and properties of PVC.

PVC 25 kg bag packaging machines help streamline the packaging process, increase productivity, reduce manual labor, and ensure consistent packaging quality. They are designed to meet the specific requirements of packaging PVC in 25 kg bags efficiently and effectively.

The features of a PVC 25 kg bag packaging machine can vary depending on the specific model and manufacturer. However, here are some common features you might find in such a machine:

1. Bag feeding system: A mechanism that feeds the empty bags into the packaging machine, ensuring a continuous supply.

2. Weighing system: A precise weighing system that accurately measures the PVC material before it is packed into the bags. It ensures consistent bag weights.

3. Filling mechanism: A system that fills the PVC material into the bags. It can use various methods such as auger fillers, gravity fillers, or pneumatic fillers, depending on the specific machine.

4. Bag sealing system: A sealing mechanism that securely seals the filled bags. This can include options like heat sealing, ultrasonic sealing, or mechanical sealing.

5. Control panel: An interface that allows operators to set and adjust parameters such as bag weight, sealing time, and other packaging settings. It may also provide machine diagnostics and monitoring features.

6. Conveyor system: A conveyor belt or system that transports the filled and sealed bags to the next stage of the packaging process or for further handling.

7. Safety features: Safety measures such as emergency stop buttons, safety guards, and sensors to ensure operator safety during machine operation.

8. Speed and productivity: PVC 25 kg bag packaging machines may offer adjustable speed settings to accommodate different production rates. They are designed to handle high volumes and maintain consistent packaging efficiency.

Filter Using Product Tags