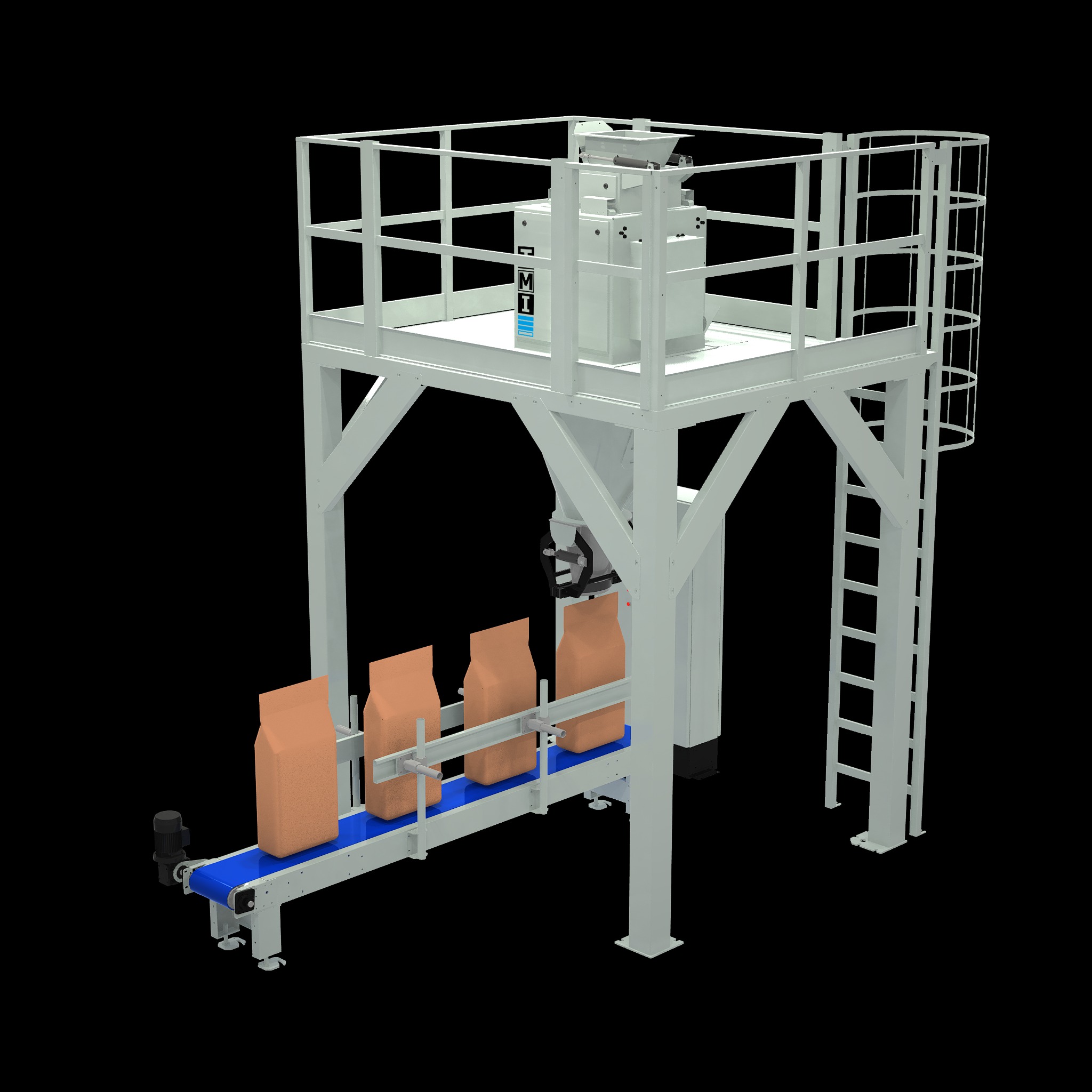

Weighing & Bagging Machine Features

Weighing and bagging machines, also known as weigh fill machines, are specifically designed to accurately weigh products and fill them into bags or containers. Here are some common features and capabilities of weighing and bagging machines:

Precise Weighing

Equipped with high-precision weighing scales or load cells to ensure consistent, reliable, and accurate weight measurements.

Bagging Flexibility

Supports a wide range of bag sizes and materials, including plastic, paper, and woven bags, for versatile packaging requirements.

Speed & Efficiency

Designed for high-speed operations, enabling rapid weighing and bagging of multiple products per minute to save time and boost productivity.

Automatic Bagging

Automates filling and sealing, reducing manual intervention while ensuring consistent bagging and efficient workflows.

Accuracy & Control

Advanced control systems set target weights and adjust filling speed for precise and consistent results every time.

User-Friendly Interface

Touchscreen or control panel interfaces make it easy for operators to set parameters, monitor operations, and make adjustments.

Data Recording & Integration

Stores production data like bag count, weight statistics, and batch information. Can integrate with inventory management or barcode systems.

Safety Features

Equipped with emergency stops, guarding, and sensors to protect operators and ensure safe machine operation.

Weighing and bagging machines are widely used in industries such as agriculture, food processing, chemicals, and minerals, where accurate weighing and efficient packaging are essential. They offer a reliable and automated solution for packaging various products, optimizing production processes and reducing labor costs.