Get Your Free Quote…!

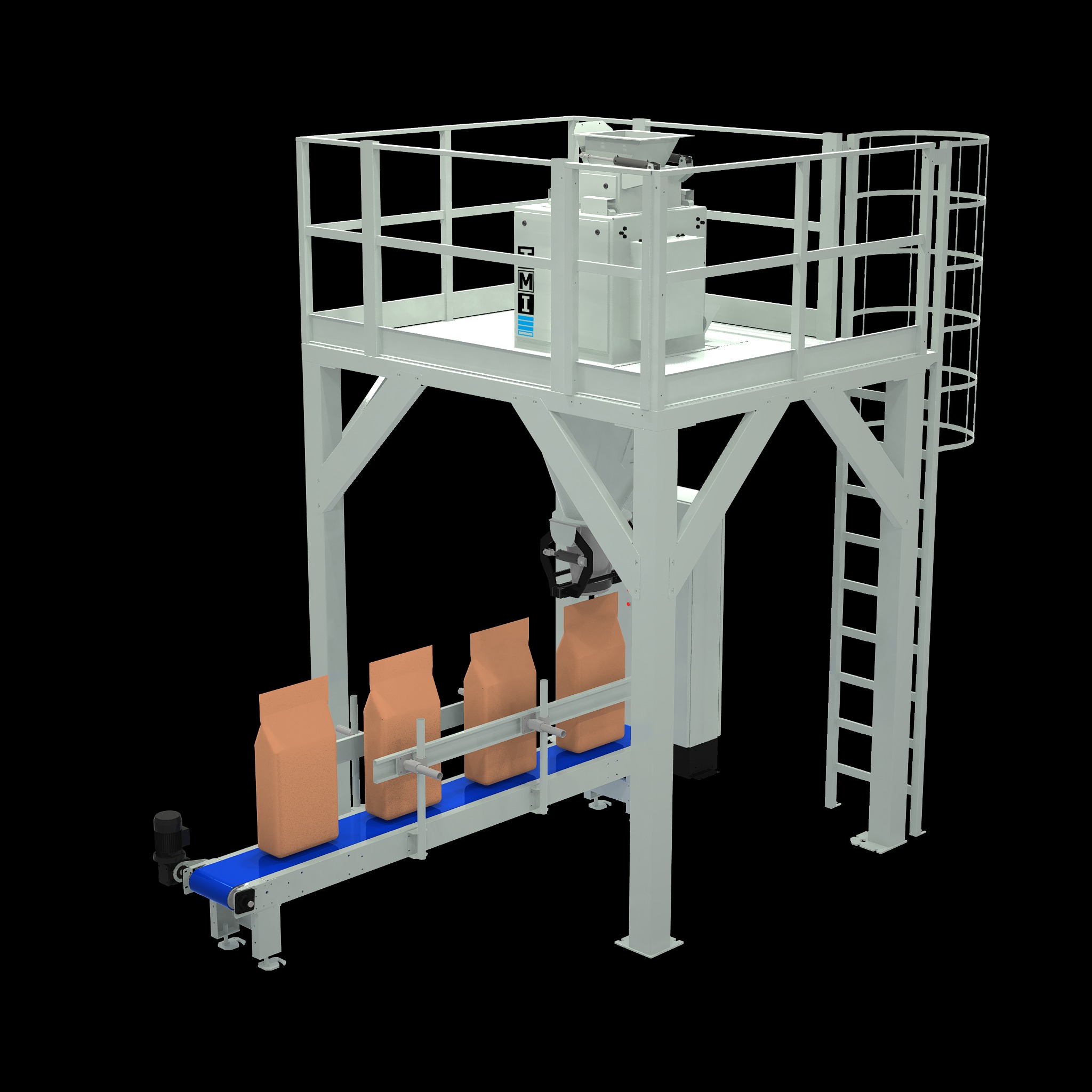

A polymer automatic bagging machine is a specialized packaging machine designed to automatically fill, seal, and label bags containing polymer materials. Here is a description of the machine and its benefits:

Description:

A polymer automatic bagging machine typically consists of the following components:

1. Bag Feeding System: This system automatically feeds empty bags into the machine from a bag stack or a continuous roll. It ensures a steady supply of bags for the packaging process.

2. Weighing and Filling Mechanism: The machine is equipped with precise weighing scales or load cells to accurately measure the desired weight of polymer material. It automatically dispenses the correct amount of polymer into each bag, ensuring consistency and reducing waste.

3. Bag Opening and Sealing: The automatic bagging machine efficiently opens bags, either by cutting or pulling them open, and seals them after filling. It may use various sealing methods such as heat sealing, ultrasonic sealing, or adhesive sealing to secure the bags.

4. Bag Conveying System: It transports the filled and sealed bags from the packaging area to the next stage of the process, such as labeling, palletizing, or further conveyance.

5. Control System and HMI: Automatic bagging machines are equipped with a control system that regulates the bagging process. It includes a Human-Machine Interface (HMI) for operators to monitor and control the machine's settings, parameters, and production data.

Benefits:

Polymer automatic bagging machines offer several benefits for packaging polymer materials:

1. Increased Efficiency: These machines significantly improve packaging efficiency by automating the bagging process. They can handle high production volumes and operate at consistent speeds, resulting in higher output rates and reduced labor requirements.

2. Precise Weighing and Filling: Automatic bagging machines ensure accurate measurement and filling of polymer materials. This eliminates human error, maintains product consistency, and optimizes material usage, reducing costs associated with overfilling or underfilling bags.

3. Time and Labor Savings: By automating bagging operations, these machines save time and labor compared to manual bagging methods. Operators can focus on monitoring and managing the process rather than physically handling and filling bags, leading to increased productivity and cost savings.

4. Improved Product Quality: The automatic bagging process ensures consistent and reliable bag sealing, reducing the risk of product contamination, moisture ingress, or spillage. This helps maintain the quality and integrity of the polymer materials, preserving their properties during storage and transportation.

5. Enhanced Safety and Ergonomics: Automatic bagging machines minimize the physical strain on operators by reducing manual handling of bags. This promotes workplace safety, reduces the risk of injuries, and improves ergonomics for the operators.

6. Customization and Integration: These machines can be customized to accommodate various bag sizes, types, and closure methods specific to polymer packaging requirements. They can also be integrated into existing production lines, seamlessly connecting with other equipment such as conveyors, labelers, or palletizers.

7. Data Logging and Traceability: Many automatic bagging machines feature data logging capabilities that capture production data, batch information, and bagging parameters. This facilitates traceability, quality control, and compliance with regulatory standards.

8. Cost Savings: The automation and efficiency of automatic bagging machines lead to cost savings in labor, material usage, and improved overall productivity. They optimize packaging operations and minimize errors, resulting in reduced waste and increased profitability.

In summary, polymer automatic bagging machines offer efficiency, accuracy, improved product quality, and cost savings. They automate the bagging process, ensure precise filling, reduce labor requirements, enhance safety, and provide customization options for specific polymer packaging needs. These benefits make them valuable assets in the polymer industry.

Filter Using Product Tags