Vacuum conveying systems offer several features that make them efficient and reliable for material handling in various industrial applications. Here are some key features of vacuum conveying systems:

Get Your Free Quote…!

Vacuum conveying system and pneumatic conveying system are two different methods used for transporting materials in industrial processes. Here's a description of each:

1. Vacuum Conveying System:

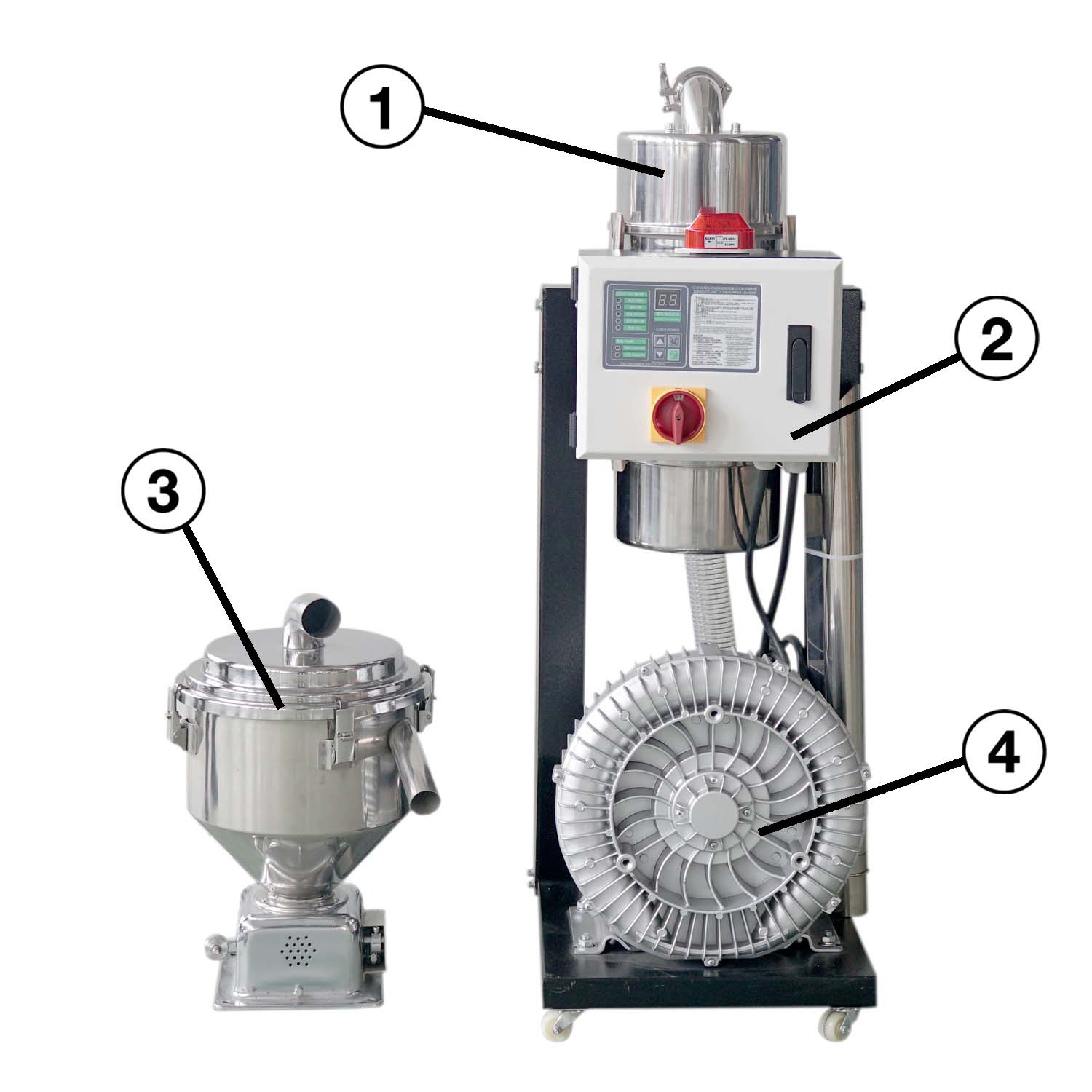

A vacuum conveying system, also known as a vacuum transport system or pneumatic vacuum system, is a method of material handling that uses a vacuum to transport materials from one location to another. It operates by creating a pressure differential, with lower pressure at the destination point compared to the source point. The system typically consists of the following components:

- Vacuum Pump: A vacuum pump generates the suction force needed to create a pressure differential. It creates a vacuum by removing air or other gases from the conveying pipeline or vessel.

- Conveying Pipeline: The conveying pipeline is a closed system through which the materials are transported. It is designed to maintain airtight conditions to enable efficient vacuum operation.

- Material Receiver: The material receiver is the destination point where the materials are collected. It can be a hopper, silo, or another container designed to receive and store the conveyed materials.

- Filters and Separators: Vacuum conveying systems often include filters and separators to remove any dust or contaminants from the conveyed materials before they reach the material receiver.

Vacuum conveying systems are commonly used in industries such as pharmaceuticals, food processing, plastics, and chemical manufacturing. They are suitable for handling a wide range of materials, including powders, granules, pellets, and other bulk solids.

2. Pneumatic Conveying System:

A pneumatic conveying system is another method of material handling that uses compressed air or a gas to transport materials from one place to another. It operates by creating a high-velocity stream of air or gas that carries the materials through a pipeline. The system typically consists of the following components:

- Air Compressor: An air compressor provides the compressed air or gas needed to generate the conveying force. The compressor pressurizes the air or gas before it enters the conveying pipeline.

- Conveying Pipeline: The conveying pipeline is a closed system through which the materials are transported. It is designed to maintain the appropriate air or gas velocity for efficient conveying.

- Material Receiver: Similar to the vacuum conveying system, the material receiver is the destination point where the materials are collected.

- Filters and Separators: Pneumatic conveying systems may include filters and separators to remove any contaminants or fines from the conveyed materials before they reach the material receiver.

Pneumatic conveying systems are widely used in industries such as cement, mining, agriculture, and chemical processing. They can handle a variety of materials, including dry powders, grains, pellets, and even liquids in some cases.

Both vacuum conveying systems and pneumatic conveying systems offer efficient and flexible methods for transporting materials in industrial processes, each with its own advantages and considerations based on the specific requirements of the application.

Vacuum conveying systems offer several features that make them efficient and reliable for material handling in various industrial applications. Here are some key features of vacuum conveying systems:

Vacuum conveying systems find a wide range of applications across various industries where the efficient and dust-free transfer of materials is crucial.

These are just a few examples of how vacuum conveying systems are utilized in different industries. Their ability to ensure efficient and dust-free material transfer makes them essential in applications where cleanliness, contamination control, and operational efficiency are critical.

Filter Using Product Tags