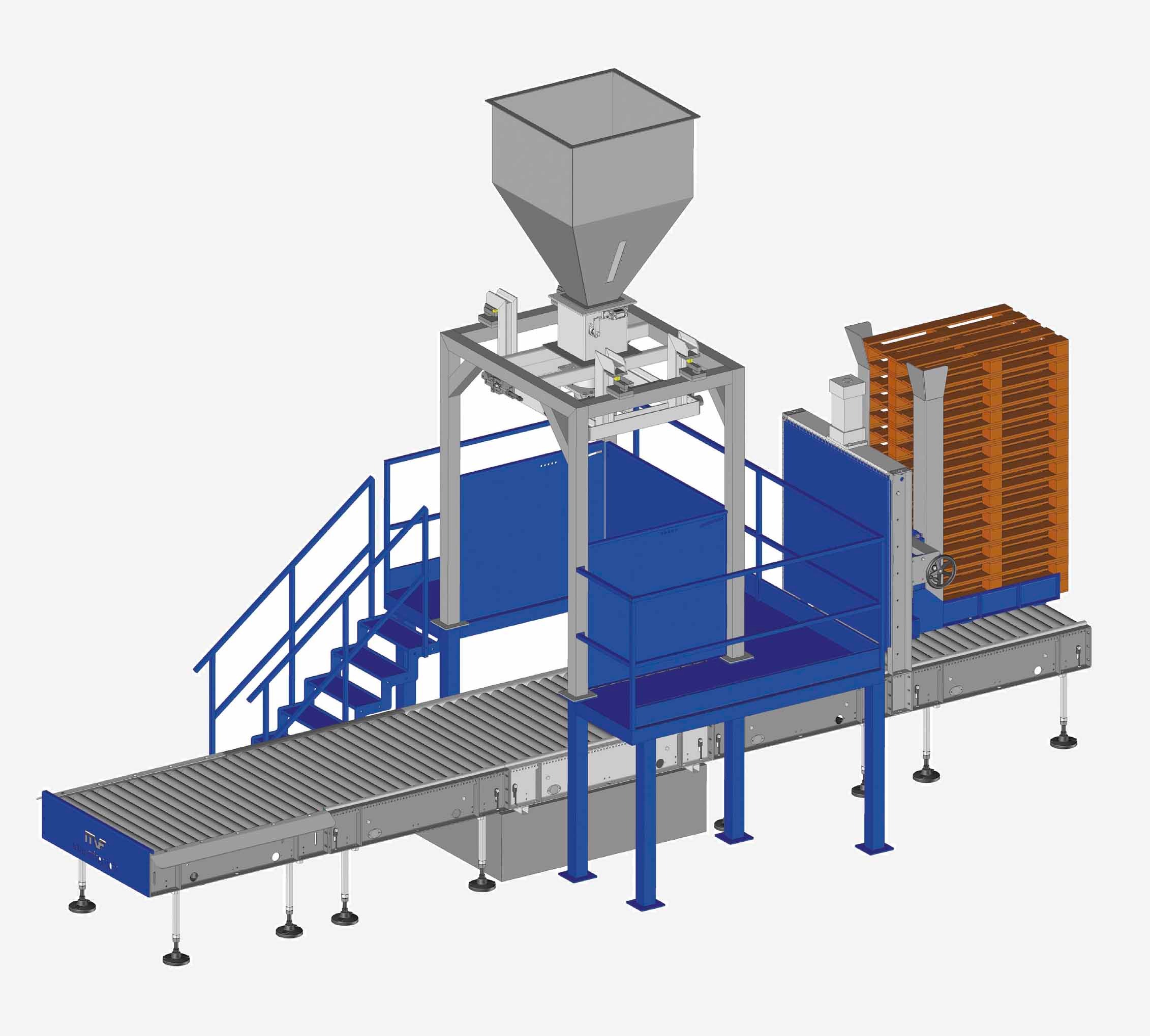

Polymer Packaging Machine

Packaging Machine Description

Packaging machine is a mechanical device designed to automate the process of packaging various products. It is commonly used in industries such as Polymer Industries, Cattle Feed Industries, Chemical Plant, Agro Industries, Fertilizer Industries. The machine efficiently and accurately packages products into containers, such as boxes, bottles, pouches, or bags, for storage, transport, or sale.

Packaging machines come in various types, including:

1. Filling Machines: These machines are used to measure and fill products into Open Mouth Bags, Jumbo Bags. They can handle powders, granules, or solids, and ensure precise and consistent filling volumes.

Overall, packaging machines improve production efficiency, reduce labor costs, and ensure consistent packaging quality. They play a crucial role in streamlining manufacturing processes and meeting the demands of modern packaging requirements.

Request A Quote