Sure! Here are some key features of pneumatic and manual slide gates:

Get Your Free Quote…!

A pneumatic slide gate and a manual slide gate are two types of gate mechanisms used in various industries and applications for controlling the flow of materials, such as powders, granules, or bulk solids. Here's a description of each:

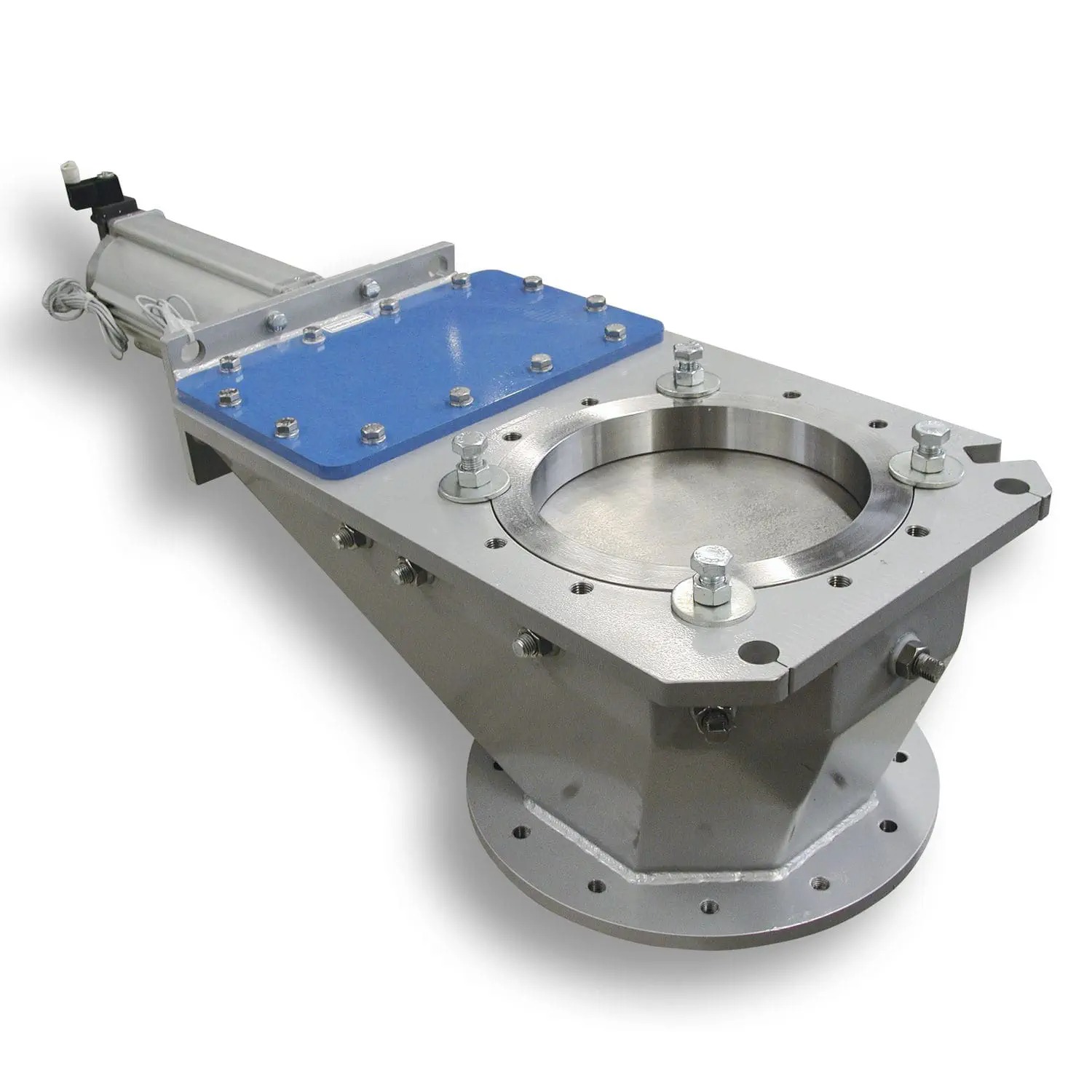

1. Pneumatic Slide Gate:

A pneumatic slide gate is a gate system that operates using compressed air or gas. It typically consists of a gate or blade that slides across an opening, allowing or blocking the material flow. The gate is controlled by pneumatic actuators or cylinders, which respond to air pressure changes to open or close the gate. Pneumatic slide gates are commonly used in industrial settings where automated control is desired. They offer quick and precise material flow control, and their pneumatic operation allows for remote control and integration into larger automated systems.

2. Manual Slide Gate:

A manual slide gate, on the other hand, is operated manually by a person. It usually consists of a gate or blade that can be manually moved across an opening, either by sliding or rotating mechanisms. Manual slide gates are often used in smaller-scale operations or situations where manual control is sufficient. They are simpler in design and do not require pneumatic or automated systems. Manual slide gates are commonly found in agricultural, construction, and small-scale manufacturing applications.

Both pneumatic and manual slide gates are designed to control the flow of materials and provide a means to shut off or regulate the passage of bulk solids through a particular pathway. The choice between the two depends on factors such as the level of automation desired, the scale of operation, and the specific requirements of the application at hand.

Request A QuoteSure! Here are some key features of pneumatic and manual slide gates:

Pneumatic and manual slide gates find applications in a variety of industries and scenarios. Here are some common applications for each:

Filter Using Product Tags