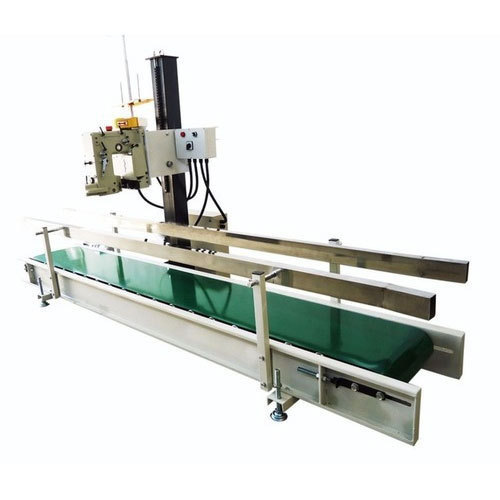

Belt Conveyor Features

Belt conveyors offer a range of features that make them versatile and efficient for material handling applications. Here are some common features of belt conveyors:

1. Versatile Design: Belt conveyors can be designed to suit various applications, environments, and material types. They can handle a wide range of materials, including bulk solids, loose items, packaged goods, and irregularly shaped objects.

2. Variable Speed Control: Belt conveyors often come with adjustable speed controls, allowing operators to regulate the conveyor's speed to match specific production requirements. This feature provides flexibility and adaptability in material handling processes.

3. Quiet and Smooth Operation: Belt conveyors typically operate smoothly and quietly, reducing noise levels in the working environment. This makes them suitable for applications that require minimal disruption or noise pollution.

4. Adjustable Incline Angle: Some belt conveyors are designed to handle inclined or vertical transportation. These conveyors can be adjusted to specific incline angles, allowing materials to be efficiently transported to different levels or heights.

5. Easy Maintenance: Belt conveyors are designed for ease of maintenance. They often feature accessible components and modular designs that facilitate quick belt replacement, cleaning, or maintenance tasks.

6. Load Capacity: Belt conveyors are available in various load capacities to accommodate different material handling requirements. They can handle light to heavy loads, depending on the belt's strength and the conveyor's structural design.

7. Safety Features: Belt conveyors prioritize operator safety. They may include safety guards, emergency stop buttons, pull cords, and sensors to detect belt misalignment, excessive tension, or other potential hazards. These features help prevent accidents and ensure a safe working environment.

8. Durability and Reliability: Belt conveyors are built to be durable and reliable, capable of withstanding rigorous industrial environments. They are constructed using high-quality materials and components to ensure long-lasting performance.

9. Customization Options: Belt conveyors offer customization options to meet specific requirements. They can be designed with specific belt widths, lengths, and heights to suit the available space and material handling needs.

10. Integration with Other Systems: Belt conveyors can be integrated with other material handling systems, such as loading/unloading stations, weighing systems, barcode scanners, or sorting devices. This allows for seamless automation and improved efficiency in material handling processes.

These features make belt conveyors a popular choice for a wide range of industries, including manufacturing, mining, logistics, warehousing, agriculture, and more. They provide efficient and reliable transportation of materials, contributing to streamlined operations and increased productivity.

Belt Conveyor Applications

Belt conveyors find extensive application across various industries and sectors where efficient material handling is crucial. Here are some common applications of belt conveyors:

1. Manufacturing and Production: Belt conveyors are widely used in manufacturing and production facilities for transporting raw materials, components, and finished products between different stages of the production process. They facilitate the smooth flow of materials, increasing productivity and reducing manual handling.

2. Mining and Quarrying: In the mining and quarrying industry, belt conveyors are used to transport bulk materials such as coal, ore, gravel, sand, and aggregates. They efficiently move large volumes of materials over long distances, enabling continuous and reliable material transport.

3. Warehousing and Distribution: Belt conveyors play a vital role in warehouses and distribution centers for sorting, merging, and transferring goods. They facilitate the movement of packages, pallets, and containers between storage areas, loading docks, and shipping zones, improving logistics and order fulfillment processes.

4. Agriculture and Farming: Belt conveyors are utilized in the agricultural industry for handling crops, grains, seeds, and other agricultural products. They are employed in grain elevators, feed mills, seed processing plants, and agricultural storage facilities for efficient loading, unloading, and transfer of bulk materials.

5. Food Processing and Packaging: Belt conveyors are extensively used in the food processing and packaging industry. They transport ingredients, processed food products, and packaging materials along various stages of production, including sorting, washing, drying, cooking, cooling, and packaging.

6. Airport Baggage Handling: Belt conveyors are integral to airport baggage handling systems, transporting checked-in luggage from check-in counters to baggage sorting areas, loading onto planes, and eventually to the baggage claim area. They ensure efficient and accurate baggage handling for air travel.

7. Retail and E-commerce: Belt conveyors are employed in retail and e-commerce warehouses for automated sorting, order picking, and distribution of products. They enhance order processing efficiency, reduce manual labor, and facilitate faster order fulfillment.

8. Construction and Building Materials: In the construction industry, belt conveyors are used for transporting bulk materials such as aggregates, sand, gravel, cement, and construction debris. They assist in efficient material handling at construction sites, reducing manual labor and improving productivity.

9. Recycling and Waste Management: Belt conveyors are employed in recycling facilities and waste management centers for sorting, separating, and transporting recyclable materials and waste streams. They enable efficient material flow and contribute to sustainable waste management practices.

These applications demonstrate the versatility and importance of belt conveyors in various industries, enabling efficient and reliable material handling, improving productivity, and streamlining logistics and production processes.