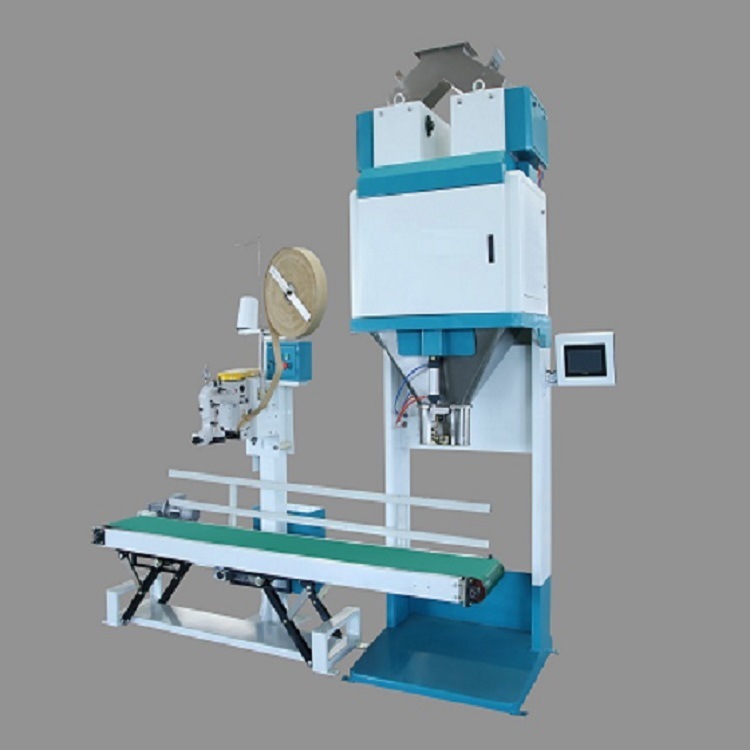

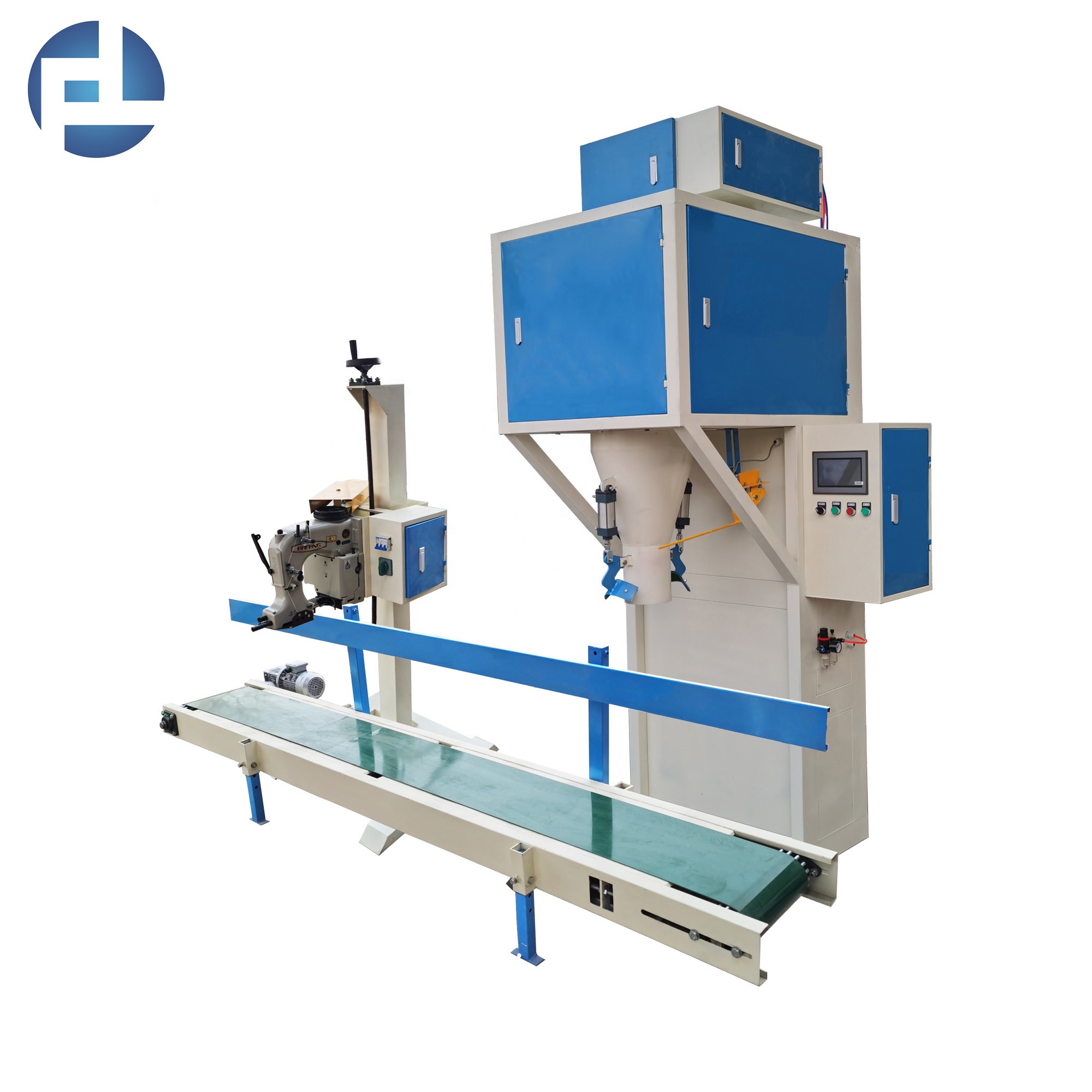

Chemical Packaging Machine Features

Chemical packaging machines come with various features designed to ensure efficient, safe, and accurate packaging of chemical products. Below are some key features commonly found in these machines:

Weighing System

Accurate weighing mechanisms ensure precise measurement of chemical powders, maintaining consistency in packaged quantities.

Feeding System

Reliable feeding system transfers chemical powder from the supply source into the packaging unit, ensuring a steady flow of material.

Packaging Options

Offers flexibility with various bag sizes, container types, and packaging materials to meet specific requirements.

Sealing Mechanism

Robust sealing ensures airtight and secure closures, preventing contamination or leakage during storage and transportation.

Dust Collection System

Built-in dust collection helps maintain a clean environment and reduces contamination or operator exposure.

Control Panel

Intuitive panel enables operators to adjust speed, weight limits, and formats easily, enhancing control and efficiency.

Safety Features

Includes emergency stop buttons, safety interlocks, and protective enclosures to ensure safe machine operation.

High-Speed Packaging

Efficiently handles large volumes of powders with high-speed packaging capabilities, increasing productivity.

Automatic Operation

Advanced models feature automatic feeding, filling, weighing, sealing, and ejection, minimizing manual intervention.

Quality Assurance

Incorporates barcode scanners, vision systems, or checkweighers to ensure accurate packaging and detect abnormalities.

These features may vary depending on the specific model and manufacturer, but they collectively ensure safe, precise, and efficient chemical packaging operations across industries.

Chemical Packaging Machine Applications

Chemical packaging machines find applications in various industries that deal with the production, distribution, and sale of chemical powders. Below are some common applications where these machines play a vital role:

Chemical Manufacturing

Extensively used in plants to package fertilizers, detergents, pesticides, dyes, pigments, and a variety of industrial chemicals.

Pharmaceutical Industry

Employed for packaging powdered ingredients used in medicines, supplements, and pharmaceutical intermediates.

Food Industry

Handles food-grade chemical powders such as additives, flavorings, spices, and food colorants safely and efficiently.

Cosmetics Industry

Used for packaging cosmetic powders like talcum, face powders, and pigments for makeup products.

Construction Industry

Specialized systems package powders like cement, adhesives, grouts, and sealants for the construction sector.

Agriculture & Gardening

Applied for fertilizers, herbicides, insecticides, and soil conditioners in agricultural operations.

Cleaning Products

Packages powdered cleaning agents including detergents, dishwashing powders, and surface cleaners.

Automotive & Manufacturing

Used for chemical powders like lubricants, metalworking fluids, and coatings in industrial operations.

Research & Development

Laboratories use these machines to package experimental chemicals, reagents, and powders for research studies.

These applications highlight the versatility and importance of chemical packaging machines in ensuring efficient, accurate, and safe packaging of chemical powders across diverse industries.